2023

TruSteel Group

We are a group of eight companies – united in steel. Our latest acquisitions are TruSteel Energy, TruSteel Infra and TruSteel Recycling.

Turnover

87

million euros (2022: 100 million). In 2023 our turnover decreased by 13% compared to 2022.

Return

Return On Equity

(2022: 11%)

6%

Solvency

54%

Employment

331

employees – 84 new employees in 2023.

Energy transition

1332

tonnes of CO2 emissions by the group. A decrease of 44% compared to 2015.

Graduated apprentices

2

apprentices obtained their diplomas.

New apprenticeships

8

learners started apprenticeships.

Gross investment

4,5 million euros

(2022: 4.4 million) Largest investment was in real estate.

Internships

11

students started internships.

Production area

Our eight divisions now occupy a production area of over

40.000 m2

Step 3

Safety Culture Ladder

All organisational units maintained their positions on

step 3

of the nationally-recognised safety ladder.

Step 5

CO2 performance ladder

All organisational units reached

step 5

of the CO2 performance ladder.

National and international customers

In addition to the Netherlands, our customers last year were from the United States, Mexico, Indonesia, Canada, the Czech Republic, Germany, England, Norway, Croatia and Italy.

Foreword

‘This competition does not end after 90 minutes‘

The Eurovision Song Contest: a cultural festival that should contribute to unity and fraternity. Which is not what happened. Supporters and opponents of all stripes locked horns. Whether concerning the Israeli contestant, the non-binary artist who won, or the disqualification of Joost Klein, reactions to the event showed deep divisions. In my view, this is indicative of the times we live in.

We also see these divisions in other areas. Consider the Russia-Ukraine conflict, issues of nature and climate, agricultural policy, pandemic containment, Palestine vs Israel, left or right. We seem to be further divided than ever. Is there still a will to understand each other?

In normal life this issue is not that visible. People do their shopping, go to work, do sports, attend a pop concert with friends – all in the usual way. Fortunately. But we need to guard against development of a breeding ground for irreconcilable differences as regards our ways of thinking. This can only be done by continuing to see, hear and be open to each other’s feelings and thoughts.

And in companies, this is the task for leaders. After all, an organisation reflects society. So how do you steer an organisation with hundreds of people, all with their own beliefs and opinions, in the right direction? Do you hold your course, in a storm, or just drop your sails?

I see this as a function of the way we address the future. While the word transition suggests that there is a start and end to the process of advancement and change, in reality there is not. The world, indeed, never stops changing. We’re not in a football match that will end after 90 minutes. This is an infinite game1 . Admittedly with intermediate goals, which at best help with navigation along the way. But this game demands different decisions. About people and collaboration. About talent management and investment. (In this context, we welcome the TruSteel brand.) And about how transitions are guided. These are decisions made with the long term in mind. So, in the context of working together, we’d better be genuinely curious about each other’s insights. Let’s search for the common ground – that exists more often than we think. Easy? No. I also find this difficult. But it is a very instructive process! And more necessary than ever – in these times. Because the future is not tomorrow, or the end of the financial year. It’s bigger than that. Those are just points where the future starts.

Unfortunately, the 2023 financial year was, indeed, finite. So, with projects starting later than originally planned, revenue was lower than anticipated. As a result, while the group’s results are stable, they also leave something to be desired. But with a record level of projects in our portfolio we have indeed started the next phase with confidence.

Read on for our report on the journey so far. And get in touch if you want to continue our journey into the future, together.

Bob Soetekouw

Managing Director, TruSteel Group

1. Simon Sinek, The Infinite Game, an interesting book for those who want to read more on this topic.

‘We create trust by showing our partners and customers that we are an experienced partner to work with who delivers quality.’

#wemakesteelwork

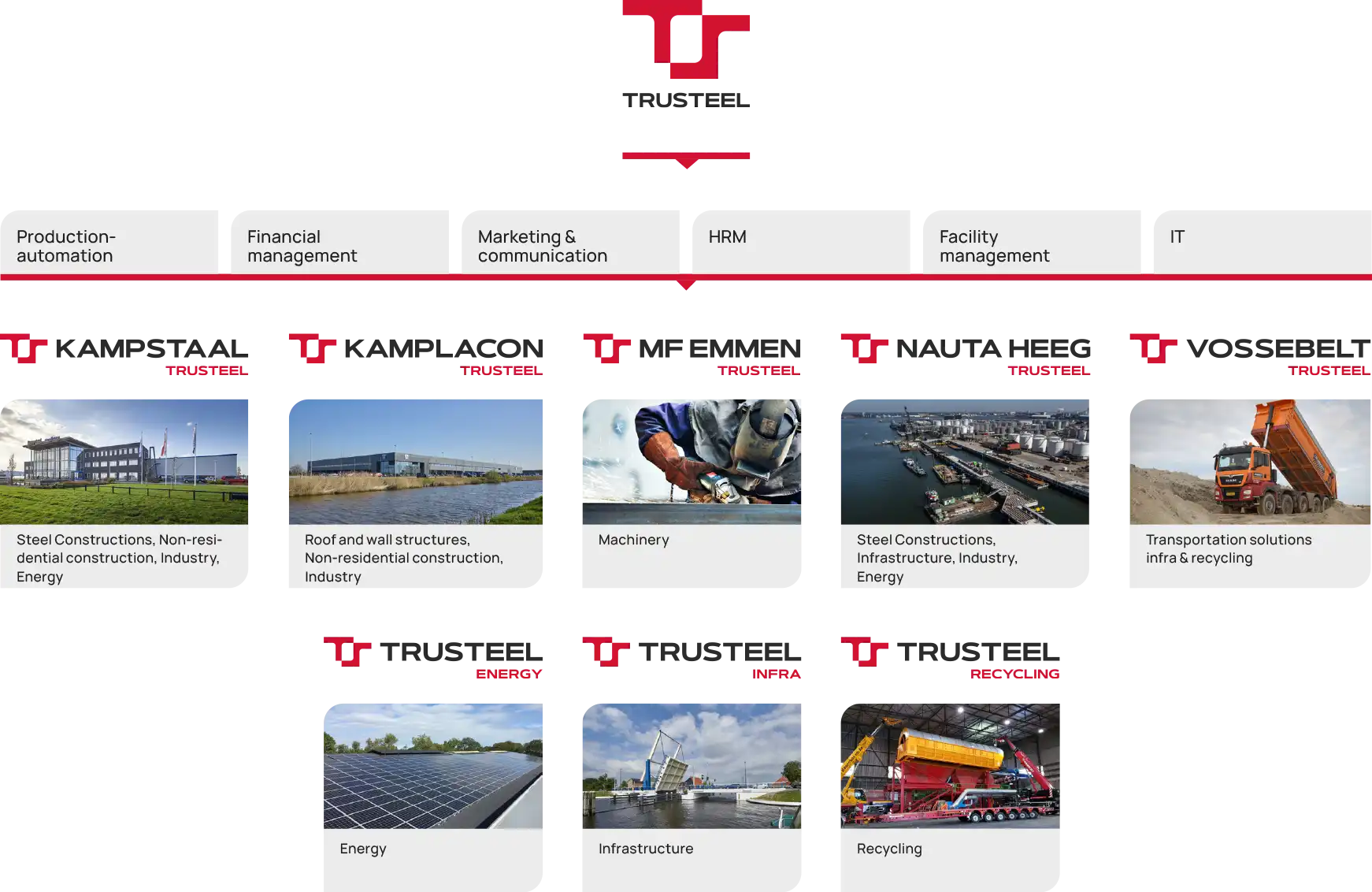

Our family of companies

TruSteel Group:

we make steel work

TruSteel Group consists of eight, steel-processing divisions that supply the international construction, engineering and transport sectors. For six years, the group has ranked among the best financially performing manufacturing companies in the Netherlands.

We serve clients in different market segments and carry out diverse projects. From steel, roof and facade structures, to bridges and locks. And from recycling plants, to tippers and containers. Our group literally and figuratively makes steel work.

| # employees | 331 |

| Solvency | 54 |

| Turnover growth 2017-2023 | 33% |

Kampstaal:

strong in steelwork

Kampstaal is well-known for steel structures for commercial and industrial construction. In the Netherlands, and far beyond, we have supplied complex support structures for car parks, data centres and other utility buildings, for over 40 years. As well as stairs, landings and structures for our electricity network, produced at our sites in Emmeloord and Meppel. We operate as a committed partner, customer-oriented and innovative, and take care of the entire process – from the designs and manufacturing to on-site assembly. This enables us to have provide good service and appropriate, customised solutions and to continue to ensure a particularly high level of quality.

Clients

In 2023, Kampstaal’s work included the Breukelen car park, an extension for WarmtelinQ in Delft and data centres near Amsterdam, Frankfurt and Berlin.

| # employees | 119 |

| Production area | 24.000 m2 |

| Turnover growth 2018-2023 | 31% |

Kamplacon:

construction partner for roof and facade structures

Kamplacon is an ambitious, innovative family business. Kamplacon develops, manufactures and installs durable roof and wall structures for customers at home and abroad. Our claddings offer attractive, high-quality solutions for new-build, renovation and maintenance projects. Working from locations in Emmeloord and Ootmarsum, Kamplacon is pleased to provide a dedicated service to clients, in a daily basis, working on a wide variety of non-residential construction projects, including data centres and distribution centres. Kamplacon provides prefabricated facades, if required, which can significantly increase the speed of construction. The advantage for the customer is that the building can be commissioned earlier, while prefabricated construction is also fully modular and demountable.

Clients

In 2023, Kamplacon worked on various data centres around Amsterdam, Frankfurt and Berlin, as well as replacing a 400-metre façade at Van Merksteijn International, in Almelo. Kamplacon frequently cooperates with sister company, Kampstaal, working together to increasingly taking on the complete construction of foundation, steel structure and cladding.

| # employees | 50 |

| Turnover growth 2018-2023 | 3% |

Vossebelt:

the specialist in customised transport solutions

Vossebelt is a leader in the production of tippers and disposal containers. Over the years, Vossebelt has also specialised in the manufacture of tyre unloaders, cover systems and special construction. The company has access to four large production buildings in Geesbrug and handles the entire process from here.

This involves an enthusiastic, skilled team, using state-of-the-art production techniques. Vossebelt manufactures all products entirely in-house, taking care of the entire process; from design and manufacture to erection and delivery. This enables the demand for both standard and customised solutions for the transport sector and governments to be met with speed and excellence.

| Number of tippers and containers delivered per year | 150 |

| # employees | 30 |

| Turnover growth 2018-2023 | 2% |

Nauta Heeg:

building on 150 years of experience

Nauta Heeg builds on 150 years of experience. A solid foundation for a successful future in steel. We supply heavy, complex steel structures, with a focus on fender systems, mooring facilities and other heavy structures for industry, infrastructure, tanks and equipment construction. Production takes place in industrial buildings with interior, 80-tonne lifting capacity. The company is located on open waterways and near metal conservation facilities, so that transport is not a problem in relation to large jobs. The company’s ability to deliver high quality, the right solution and draw on vast experience make it a welcome partner in the steel industry.

Clients

In 2023, Nauta’s work included the waiting berths and collision fenders at Den Helder, and the green screens for the city of Groningen and at the SOIJ (jetty) in IJmuiden.

| Lifting capacity in tonnes | 80 |

| # employees | 52 |

| Turnover growth 2018-2023 | 28% |

MF Emmen:

specialist in steelwork

MF Emmen is a machine builder, with around 70 employees. Our extensive range of machinery provides solutions for customers in industries ranging from energy to food technology. We focus on developing and realizing effective solutions for the production processes of our customers. We do this by providing a comprehensive range of services; from turnkey projects to installation work and servicing.

With a wide range of disciplines in-house, far-reaching mechanical knowledge, the necessary certification and qualified employees, MF Emmen is a reliable partner for every customer.

Clients

In 2023, MF Emmen’s work included the construction of several plants and filter tanks, including work for Cosun Beet Company, in Breda.

| # employees | 70 |

| Turnover growth 2018-2023 | 40% |

TruSteel Energy:

your partner for smart energy solutions

TruSteel Energy is an experienced solar energy partner. We have fitted many roofs with solar panels in recent years. TruSteel Energy offers a single point of contact and supplies complete, new solar panel systems for customers, including connection to the public grid. Besides solar panels, TruSteel Energy also specialises in other energy solutions, such as energy storage (attractive in cases of grid congestion), energy management systems and charging stations.

Clients

In 2023, TruSteel Energy again fitted multiple roofs with

solar panels, including at Gouweleeuw in Emmeloord, De Golfslag apartment complex in Emmeloord and at Wentink Groente in Luttelgeest.

TruSteel Infra:

specialised in complex steel construction (water) works

TruSteel Infra contributes to keeping the infrastructure of the Netherlands safe, accessible and live-able. TruSteel Infra focuses not only on new expansion of infrastructure, but also on the major renovation and replacement task facing the Netherlands over the coming decades.

TruSteel Infra works together with its clients and partners to achieve this. Together we build smart, sustainable solutions for complex steel construction (water) works, including bridges, locks, dams and pumping stations.

Clients

The TruSteel Infra division works largely for government and local authorities, such as the Department of Public Works, provinces, municipalities and water boards. In 2023, TruSteel Infra’s work included the construction of the Brug Bedum bridge, Gerda Tarobrug bridge in Amsterdam, and the Pijlebrug bridge in Havelte.

TruSteel Recycling:

trusted partner for waste recycling solutions

TruSteel Recycling is a leading supplier of complete recycling solutions and individual components. TruSteel Recycling focuses mainly on sorting solutions for the processing of construction, demolition, industrial and green waste. TruSteel Recycling supplies components that include sieve drums, air separators, danodrums and conveyor belts, as a complete

recycling line, directly to customers, and also offers individual components for separating various waste streams. Existing installations can also be adapted or expanded if required. With its expertise and years of experience, TruSteel Recycling has provided recycling solutions to a wide range of industrial categories. The organisation is set up to operate both nationally and internationally under various contractual forms.

Clients

In 2023, TruSteel Recycling’s work included the construction of several recycling plants for waste processors such as Prezero and Omrin, as well as for customers in southern Europe.

Family business

We are a proud family business that has built a wide variety of projects in different market segments, with genuine passion and drive, for more than 40 years. Today we can list an impressive collection of buildings, bridges, locks, recycling plants, tippers & containers as our achievements. We focus on the national and international markets.

With a turnover of €87 million and over 350 employees, we are now one of the larger industrial employers in the north of the Netherlands. Our core business includes the design, development and construction of a variety of projects, as well as assembly, renovation and maintenance.

Rebranding-process

GB Steel Group will become the TruSteel Group

In 2023, we started a rebranding exercise. GB Steel Group has implemented a

name change, and become the TruSteel Group. We want our divisions to operate as independent organisations within the TruSteel Group, and that this will be reflected in a new corporate identity.

The new name and corporate identity will exude more unity and connection. The new name TruSteel matches our ambition and core values. We are trusted, in delivering quality and honouring our commitments. We are actualisers who do what we promise and stand by what we do. We do everything with truth and integrity. This is what we stand for and how we behave and operate, as a group. With regard to each other, our clients, our cooperation partners and the society in which we participate.

Three new divisions

We have chosen to rename some operations. This applies to the infra, energy and recycling markets.

Benefits from the introduction of TruSteel Infra

Previously our divisions Nauta Heeg and Machinefabriek Emmen often worked together on building a number of bridges and locks. It was therefore a logical step, given this intensive cooperation, to unify all activities under one name.

TruSteel Infra is now the name under which we work on bridges, locks, dams and pumping stations. The reliable nature, quality and craftsmanship built by both preceding brands will continue, as TruSteel Infra has the same employees and services, remaining a reliable partner for customers and collaboration partners.

As always, production and assembly are housed at the production sites of Nauta Heeg and Machinefabriek Emmen. However, customers will now have one, central point of contact for applications and tenders regarding bridges and locks.

Benefits from the introduction of TruSteel Energy

Customers could turn to Kamplacon for durable roof and facade structures, with or without supply and installation of solar panels. With high energy prices, the demand for solar panels has continued to grow, with increasingly more requests for complete, new solar panel systems. The team therefore felt the need to expand these services and place them in a dedicated division – TruSteel Energy.

TruSteel Energy now offers customers a comprehensive range of high-quality, sustainable energy solutions. Besides solar panels, we also specialise in other energy solutions, including energy storage (attractive in cases of grid congestion), energy management systems and charging stations.

As a result, we can continue to respond to our customers’ growing demand for sustainable solutions and, with them, make a significant contribution to energy transition.

Benefits from the introduction of TruSteel Recycling

Machinefabriek Emmen has more than 30 years of exemplary experience in the design, production and implementation of high-quality, waste recycling solutions.

Previously, we mainly served customers in the Netherlands, but in recent years we have also seen increasing demand for recycling plants and components from customers abroad. In order to also have a strong international profile, we have therefore chosen to house our international activities in a dedicated division: TruSteel Recycling.

TruSteel Recycling will continue operations at the same production site and with the same employees, in Emmen.

Management

All TruSteel Group companies will operate in the market under their own name and under their own management teams. Collaboration and synergy are key themes within TruSteel Group. We also want to continue developing as a group in various areas, e.g. human capital, QHSE management systems and ICT.

TruSteel Group is governed by a management team, consisting of a managing

director, a number of directors, a group financial controller and an HR Manager. The financial department is supervised by the group controller. Above the management team is the management board, formed by group managing director, Bob Soetekouw, and sales director Rieks Jansen. The management reports to the supervisory board, established in accordance with the legal requirements for companies.

A functioning works council already existed. A few women are members of the group and divisional management teams, the staff of GB Steel Group and the Supervisory Board – but women remain in the minority. HR policy addresses this inequality and aims to balance it.

Core values

As a family business, we focus on creating lasting relationships with our customers, employees and partners. In doing so, we always act on the basis of our four, core values: safety, truth & integrity, building trust, and passion for steel.

Safety

Safety is a top priority of TruSteel Group. Here safety mode is ‘always on’! Which is why we are committed to continuous improvement of safety awareness in our organisation. We share knowledge, maintain strict safety policies and motivate employees to be aware of safety risks. And, where necessary, we take measures to prevent unsafe situations.

Thus, we aim to reduce the number of unsafe events and therefore experience fewer incidents (e.g. absenteeism and accidents). In addition, we consider it of great importance to the group that our employees are healthy, safe and enjoy their work. Which is why we continue to invest in creating a safe environment.

Truth and integrity

Truth and integrity are at the heart of everything we do. We operate on the belief that behaviour based on integrity must be embedded in our organizational culture. This applies to everything we stand for as a group, our attitudes, and how we act. In relation to each other, and also in relation to our clients, business partners and the society of which we are a part. Honesty, ethics and transparency are the basis for this.

We are a trustworthy and honest company, regarding which our clients may rightly have high expectations. It is therefore our aim to create value with our steel products and to always exceed our customers’ expectations.

Building trust

At TruSteel Group, we design, produce and deliver high-quality projects in steel. We have accumulated years of experience in creating customised solutions. But we not only build great projects, we also build lasting relationships with our clients.

We create trust by demonstrating to our customers that we are an experienced partner. We believe it is important to do business in an open and honest way. We listen to our customers, establish clear agreements, and honour them. This builds trust and long-term relationships with our customers.

Passion for steel

What drives us is our passion for technology. We like construction challenges in non-residential construction, infrastructure, transport and industry. With a passion that ensures that we enjoy providing solutions to our clients’ requirements and challenges.

We understand all too well that there are many questions and few answers at the commencement of a project. Which is why our structural engineers, engineers and project managers are always delighted to help our clients answer these questions, find solutions and bring designs to fruition. With the same passion, we then ensure that the design comes to life, so our client can benefit from the desired, valuable solution. #wemakesteelwork

Engaged with society

As a family business, we feel responsible for the world around us, now and for the future generation. We are aware of the effects our activities have on our environment and aim to minimise our impact on the climate in all our work. Our CSR policy is fully focused on this. Together with our construction partners, we are always thinking about how to increase our societal contribution, and build as sustainably as possible.

We also consider it important to be socially engaged with the regions and communities in which we operate. So we support many local cultural, sporting and social events and associations. We also support many charities, as suggested by our own employees, being ones in which they are personally involved. And we work extensively with schools and various training institutes to enthuse young talent about careers in engineering.

‘Together with our employees, customers, and partners, we are making a difference today for the world of tomorrow’

‘At Vossebelt, we use modern production techniques and a skilled team to develop customised solutions for the transport sector and government bodies’

Our impact

Sustainability themes like climate adaptation, CO2 reduction, circular business and energy transition are all high on society’s agenda. So too with us. As a family business, we want to make a valuable contribution in this regard.

We achieve this by deliberately making well-considered operational decisions

based on our premise of doing business sustainably, responsibly and with respect for people and the environment. Of course, we are also actively building on the intent of the Steel Construction Accord (Dutch: Bouwakkoord Staal).

Our sustainability ambitions

In order to be able to offer our society of today, as well as future generations, a pleasant, live-able world, major improvements are still needed on many fronts. The UN has distilled this vast field of social issues into 17 concrete goals for 2030. These are the sustainable development goals, or SDGs. TruSteel Group contributes to the achievement of these goals and has included them in its sustainability strategy.

Our sustainability themes focus in particular on six of the seventeen Sustainable Development Goals, because our activities have the greatest impact on these. In broad terms, these are; developing affordable, clean energy; creating jobs and economic growth; industrialising and building infrastructure; developing sustainable buildings, cities and communities; promoting responsible production and climate action with the initial focus on CO2 footprint. We also aim to score well on the other goals.

Our internal efforts

Implementation of the sustainability strategy means we are fulfilling our mission to create healthy living environments. Our main pillars here are being smarter and more sustainable in all our projects and business processes. This means we will continue to invest in innovative technologies and materials, to reduce our carbon footprint and contribute to a circular economy.

Furthermore, our approach consists of generating renewable energy by using solar panels (from TruSteel Energy) on our own roofs, encouraging reuse and circular construction, and committing to EV transport. As a result, we want to promote the reuse of buildings, products, materials and raw materials and further reduce our CO2 emissions. We have already reduced these by 44% between 2015 and 2023.

In the coming years, we want to bring this down even further. This is because we feel it is important to take this responsibility as a group and work together to create a clean, green, safe living environment.

Promoting manufacturing industry

We believe it is important to put engineering on the map in our region. We do this not only by strengthening our own position as an attractive employer, but also by working jointly with schools and other companies within our industry to improve the image of the construction sector.

How we do it

Innovation cluster Noordoostpolder – innovating together

Together with nine companies from the manufacturing industry, we formed the Noordoostpolder innovation cluster in 2020. As well as aiming to enthuse schoolchildren and students about working in engineering, we also want to share our knowledge, provide growth opportunities to our people and innovate together.

Apprenticeship pathways – learning from the very best

We offer students challenging Apprenticeship learning-while-working positions. The Apprenticeship pathway allows apprentices to attend college one day a week and work three or four days a week, at one of our locations. Here, they learn from the very best in the field. We offer various Apprenticeships, ranging from level 2 secondary vocational education to courses at vocational university level.

Open days at schools – enthusing young people

We can be found every year at Techniek Tastbaar (technical education events for secondary school pupils), in Emmeloord, Hoogeveen and in Sneek. We are also present at the On Stage careers events. During these open days we run various workshops and offer opportunities for young people to experience the ‘work’ themselves.

School visits to the company – investing in young talent

We also believe it is important to introduce children to our companies and technology at an early age. We therefore give guest lectures in schools and regularly open our doors to primary and secondary school students. We then give guided tours and fun workshops to show how great working in engineering can be.

‘We regularly open our doors to primary and secondary school students to proudly show how great a job in engineering can be!’

Lookback

Results, financial year 2023

While TruSteel Group’s results are stable and healthy, we definitely see room for improvement. Capacity utilisation was lower than expected, largely due to delayed starting of non-residential construction projects and lower intake in infrastructure. There are also bright spots our order book ended 2023 at a record high.

TruSteel Group’s sales in 2023 were down just under 13% compared to 2022. Variable costs also decreased, partly due to normalised steel prices. Steel prices were a lot higher in 2022 after Russia’s invasion of Ukraine. Gross margin did increase, but inflation caused higher fixed costs, resulting in a lower net profit than in 2022.

The volume of work decreased slightly at almost all companies, except Vossebelt. At Kampstaal and Kamplacon, although the order book was very strong, construction of some data centres started later than expected, resulting in a decrease in capacity utilisation. At Kampstaal, previous investments in machinery also created logistical challenges, which contributed to lower results at Kampstaal. Kamplacon is less sensitive to lower capacity utilisation, because of a larger, more flexible workforce, so the result here was up to par.

Capacity utilisation was also lower in infrastructure. The task of replacing and renovating bridges and locks in the Netherlands is growing, as few new works are coming onto the market, while maintenance is becoming increasingly overdue. Capacity utilisation at TruSteel Infra, with its production sites at Nauta and MF Emmen, fell as a result. Structural hydraulic engineering and industry did provide Nauta with sufficient capacity utilisation and stable results.

In contrast, at MF Emmen, the other market segments could not contribute enough to higher utilization, so MF Emmen ended the year in the negative. Vossebelt did have a higher turnover, due to a good order book. At Vossebelt, we are seeing increasing success in managing complex customisation logistics. However, incidental organisational costs caused the result to increase only slightly compared to previous year.

In terms of environmental results, we once again reduced CO2 emissions last year. Due to the acquisition of Machinefabriek Emmen, we now compare results with a new reference year, 2021. Over the last two years, the absolute reduction has been 18%. And if we also consider the increase in activity in terms of hours, since 2021, the reduction becomes 27%. These results were mainly achieved by using solar panels, purchasing wind-generated power, deploying EVs and using LED lighting in production buildings and offices.

Besides reduction within our own companies, we also cooperate on improvement projects within the chain. For example, we are front runners in the Steel Construction Accord, and have been certified for CO2 performance ladder step 5 since 2023.

The stable results of this and previous years continue to ensure the solid financial basis of our business. Solvency remains at the very healthy level of 54% which, together with good liquidity, further contributes to TruSteel Group’s reliability as the partner for challenging projects.

Turnover and profit on equity capital

![]() Construction and recycling transport

Construction and recycling transport ![]() Steel construction infra-industry

Steel construction infra-industry![]() Commercial-industrial structures & cladding

Commercial-industrial structures & cladding

![]() Return on equity

Return on equity

Investments

At TruSteel Group, we believe in the future. That means we are always investing. We approve a multi-year investment programme annually, and periodically update it. This not only allows us to continue working with up-to-date equipment, but also prevents us from being surprised by unexpected expenses. Moreover, it allows us to focus on our strategic agenda.

Even smaller investments can have a big impact. The use of cobots, for example, gives our employees a low-threshold introduction to automatic welding and programming. In 2023, we commissioned a cobot at Nauta, having previously learnt to use them at Kampstaal in Meppel and in Emmeloord. Larger investments are prepared with multidisciplinary teams and worked out together with our partners. In 2023, for example, we completed the implementation of the new beamline for Kampstaal. A challenging project, as we chose a different logistics routing from that of the previous machine, and this also required modifications to the building. This machine line prepares Kampstaal for further automation, robotisation and optimisation of its production process.

A further investment involved the acquisition of real estate near the Kampstaal and Kamplacon sites. For this and future investments we took out an additional long-term loan, with a term of 10 years.

Investments 2022, 2023 en 2024

X € 1.000

![]() 2022

2022 ![]() 2023

2023 ![]() 2024 (prognosis)

2024 (prognosis)

Debt / EBITDA

Solvency

Return on equity

Current ratio

Highlights 2023

Vossebelt at Technische Kontact Dagen (TKD)

School visit to Nauta in Heeg

Smart angle sensors used by Vossebelt

Strategic direction

In 2021 we started the new, 2021-2024 strategy period. The focal points of this strategic plan are;

• Strengthen our position in a number of growth markets

• Invest in sustainability, digitalisation & innovation

• Develop organisation and talent

Achieve a leading market position

TruSteel Group has the ambition to grow and reach the top of the Dutch manufacturing industry. We want to strengthen our position in a number of growth markets and conquer new markets, increasingly also operating outside the Netherlands. We aim to achieve this by providing excellent construction supervision and engineering, applying smart, sustainable solutions, and improving our marketing, which included deployment of our new TruSteel brand.

In addition, we want to work even more closely between our eight divisions, within the group. By exploiting economies of scale and pooling knowledge, we can serve our customers even better, with appropriate, sustainable solutions. Together we oversee the entire chain, from concept to realisation. This enables us to take care of the entire process for our customer. And, by continuously investing in innovation and digitalisation, we can at the same time continue to respond to our customers’ changing demands.

Sustainability and innovation

Sustainable business remains an important theme within TruSteel Group. We want to fulfil our customers’ needs with solutions that minimise the impact on the environment and on our society. We do this by developing sustainable solutions for the recycling industry – for example by using smart technologies and with circular steel construction.

Making our own operations more sustainable also plays an important role. We design our business processes as efficiently as possible and actively work to reduce our own CO2 emissions. We generate renewable energy through solar panels and promote the reuse of buildings, products, materials and raw materials. This ensures that we minimise our own environmental footprint and continue to successfully build a future-proof living environment.

We are also building our own futureproofing by exploiting opportunities in the field of digitization and automation. Our targeted projects are aimed at implementing IT hardware and software that allow our employees to work together, independent of time and place constraints, which will further streamline our processes. And we are preparing our production processes for the application of robotisation, in order to speed up our customised production processes.

Organisational and talent development

Our employees are our number one priority. We therefore see it as our responsibility to create a safe, healthy working environment, in which our employees can perform at their best and continue to develop themselves. We offer plenty of opportunities and development possibilities to this end. As skills development is extremely important for our growth as an organisation.

Besides investing in their own employees, the growth of our divisions also requires them to attract new talent. Finding and hiring professionals with the right expertise remains a major challenge at this time. Which is why our recruitment activities are being professionalised and the divisions are focusing even more on employer branding and labour market communication.

In addition, we want to provide support in strengthening the ability of the education process to better align education with the needs of the labour market. We want to be among the most attractive and safest employers within our sector. In addition, we want to provide support in strengthening the ability of the education process to better align education with the needs of the labour market.

Outlook

Market developments and looking ahead to 2024

As mentioned earlier, TruSteel Group started the year well, with a record number of projects in its portfolio. The order book is particularly good in the non-residential construction and transport sectors.

There are signs of contraction within non-residential construction in the Netherlands, partly due to nitrogen and PFAS issues and complexity in permit issue. Yet we have not seen this contraction at TruSteel Group. Kampstaal and Kamplacon are increasingly less dependent on the Dutch market, and are also increasingly active in Germany. This concerns projects in which our construction expertise, reliability and flexibility are seen as added value, and where safe and orderly working processes are considered very important. Together with our partners, Kampstaal and Kamplacon supply complete steel packages, from roofs, to roofing material and (green) facades.

The task of replacing and renovating bridges and locks in the Netherlands has only increased in recent years, as the number of works requiring maintenance or replacement has increased, while insufficient new works have come onto the market. The process remains stalled at the level of (local) government and consulting engineering firms. This is unfortunate, as significant investment has been made in the manufacturing industry in preparation for this task. With the introduction of TruSteel infra as a new business unit, TruSteel Group continues to focus on this market and continues to invest in the unit to better serve the market.

Regarding other infrastructure works in structural hydraulic engineering, Nauta remains active in the construction of fender systems and mooring facilities. This work is progressing steadily, showing that our professionalism and practical location in relation to waterways and steel conservation resources is well-appreciated by our partners.

‘TruSteel Group started the year well with project portfolio of a record value’

In recent years, Vossebelt has built up a good position as a builder of customised tippers, where quality and ease of use are considered important. Here we see a clear shift towards zero-emission transport, mainly for the GWW sector in urban areas. Vossebelt has gained a lot of knowledge and experience in this context, and can adapt well to this shift. The question is what effect changes in laws and regulations will have on market demand. All the more so with the formation of a new cabinet that has a new direction in mind. However, we consider it good, in terms of confidence in politics and certainty in the marketplace, that there will be a new cabinet after a long period in which the government has been characterised by resignation or caretaker status. Vossebelt is in any event ready for the switch to emission-free transport. We also continue to focus on closer cooperation with Machinefabriek Emmen, in terms of design as well as shared production knowledge and capacity.

As far as we are concerned, the many challenges in the market in the areas of environment, labour, digitalisation and automation continue to call for close cooperation – both within the group and within the chains. Smarter, trusting cooperation, extensive knowledge and expertise and solid organisation will take us forward. TruSteel is building an organisation that is ready for tomorrow. We therefore look to the future with confidence. Build together with us!

A very successful Open Day at Kampstaal & Kamplacon

Installation of our solar panels at the Golfslag

Construction of data centres at home and abroad