2024

TruSteel Group

A group of makers that truly makes steel work.

Revenue

€122

million (2023: €87 million).

In 2024, our revenue increased by 40% compared to 2023.

Return

Return on equity (2023: 7%)

16%

Solvency

52%

(2023: 54%)

Employment

354

employees.

74 new colleagues joined us in 2024.

Energy transition

1484

tonnes of CO2 emissions across the group.

A reduction of 10% compared to 2021.

Or: 2.3 kilos per worked hour 33% reduction compared to 2021.

Graduated BBL students

1

student successfully completed their BBL track.

New BBL students

12

students started a BBL program.

Gross investments

€4,7 million

(2023: €4.5 million).

The main investments were in machinery.

Internships

17

students started

an internship.

Production floor space

Our eight divisions now occupy a production area of over

40.000 m2

Safety Culture Ladder

Step 3

All divisions maintained

Step 3

on the nationally recognised Safety Culture Ladder.

CO₂ Performance Ladder

Step 5

All divisions maintained

Step 5

on the CO₂ Performance Ladder.

National and international

clients

In 2024, we served clients not only in the Netherlands but also in the United States, Indonesia, Canada, the Czech Republic, Germany, the UK, Ireland, Norway, Croatia, and Italy..

Foreword

Patience, craftsmanship and trust pay off

Does truth still matter?

With over 5 billion social media users and AI bots as your new best friend, it’s a fair question to ask: does anyone still care where the line between fact and fiction lies? If it sounds logical and feels right, it must be true — right? More and more, truth seems to be the opinion of the majority. We seek our own version of reality, while talk show experts and media fact-checkers try to keep us on the straight path. All in pursuit of consensus. Groupthink has been elevated to a new art form.

Let’s be honest: forming groups is nothing new. What used to be preached from a soapbox now spreads rapidly through vlogs and podcasts. Belief is no longer the exclusive domain of the church. And belief, unfortunately, is not the same as reality. In fact, the battle for believers — for followers, for likes, for ‘truth’ — is fueling ever-deeper polarisation. At times, it feels like a modern-day iconoclasm. Not exactly helpful for mental health, and certainly not for the investment climate.

What does that ask of leaders?

Leaders today face the difficult but rewarding task of finding shared values. Of telling stories that are transparent about intent and motivation. Of listening, sensing, and continuously seeking the right balance. I don’t always know for sure either. But those who keep listening, keep learning. And those who keep learning, keep moving forward.

And then there’s steel

A material often associated with chimneys, smoke, and emission debates — like Tata Steel. Canceled, in favour of timber? Of course, we at WC Eend take a more nuanced view. Yes, steel production must become greener. And yes, timber is beautiful — as long as you accept the 80-year wait and the significant quantities of glue, wood mass (and money) needed to match the same load-bearing capacity.

The facts: over 90% of structural steel is made from recycled material. It lasts for generations, can be reused repeatedly, and scores surprisingly well in the Dutch Environmental Database. When used wisely, steel is a rock-solid choice for sustainable construction. Real steel. TruSteel. I recently had a great conversation about this with my new buddy ChatGPT. Read more about it later in this report.

In closing

When assessing our performance, nuance matters too. 2023 was a challenging year, with projects that started more slowly than expected. Had we suddenly forgotten how to do it? Of course not. The record results of 2024 prove: patience, craftsmanship and trust pay off. You’ll find the honest story — as you’ve come to expect from us — in this new annual report. Enjoy the read!

Bob Soetekouw

Managing Director, TruSteel Group

’Together we make steel work’

#wemakesteelwork

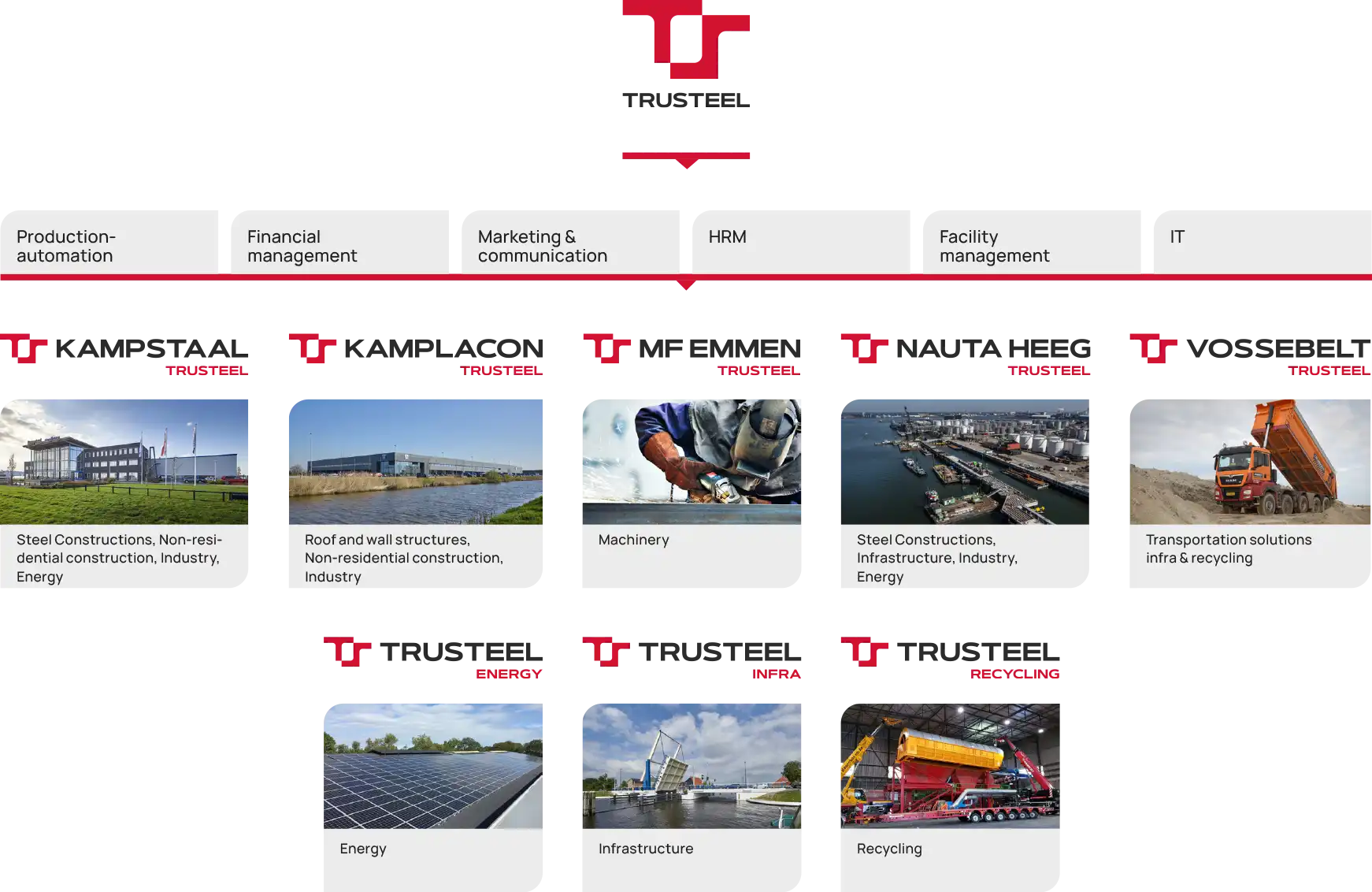

Our family of companies

TruSteel Group:

we make steel work

TruSteel Group consists of eight steel-processing divisions supplying the international construction, infrastructure, industrial and transport sectors. We serve clients across various markets and carry out a wide range of projects. From steel, roof and façade structures to bridges and locks, and from recycling installations to tippers and containers — our group quite literally makes steel work.

| FTE | 328 |

| Solvency | 50 |

| Revenue growth 2019–2024 | 80% |

Kampstaal:

Experts in structural steel

Kampstaal is a well-known name in steel structures for utility buildings, industry, and the energy sector. For over 45 years, we have delivered complex load-bearing constructions for parking garages, data centres and other utility buildings in the Netherlands and beyond. We also manufacture stairs, platforms and structural components for the electricity grid at our sites in Emmeloord and Meppel.

The full process — from design and production to on-site assembly — is carried out by our skilled employees. Thanks to modern production halls, a well-equipped machinery fleet and continuous investment in people, equipment and expertise, we maintain a consistently high quality standard. As a dedicated partner, Kampstaal always goes the extra mile to deliver complete and tailored solutions.

Clients

In 2024, Kampstaal was involved in several high-profile projects, including the construction of the parking facility at Ahoy Rotterdam, a pedestrian bridge for Royal FloraHolland in Aalsmeer and work on the WarmtelinQ project in Delft.

| FTE | 121 |

| Production space | 24.000 m2 |

| Revenue growth 2019–2024 | 163% |

Kamplacon:

Your partner in roof and façade structures

Kamplacon has long been a specialist in developing, producing and assembling sustainable roof and wall structures for commercial and utility buildings. From our locations in Emmeloord and Ootmarsum, our skilled professionals work on a broad range of new construction, renovation and maintenance projects for clients in the Netherlands and abroad.

With our professional approach, collaborative mindset and advanced production facilities, we provide effective solutions for even the most complex building challenges. Together with sister company Kampstaal, we deliver complete construction projects — from foundations to steel and cladding — at a high level of quality. As a reliable partner, Kamplacon aims to provide clients with solid, visually appealing roof and façade solutions.

Clients

In 2024, Kamplacon contributed to the construction of several data centres in Amsterdam, Frankfurt and Berlin. The company also delivered standout projects for Friesland Campina and De Groene Agri in Rutten.

| FTE | 54 |

| Revenue growth 2019–2024 | 34% |

Vossebelt:

Specialists in customised transport solutions

Vossebelt is a forward-thinking company offering innovative and highly efficient material transport solutions. In four production halls in Geesbrug, our expert staff manufacture tippers, hooklift containers, floor systems, belt unloaders and custom-built transport equipment.

Vossebelt designs, produces and assembles all products in-house — from engineering to final installation on truck and trailer chassis. Vossebelt products stand out thanks to their high standards in quality, safety and finishing, and are designed to perform under the most demanding conditions.

| Tippers and containers delivered annually | 100 |

| FTE | 29 |

Nauta Heeg:

Building on 150 years of experience

Nauta Heeg With 150 years of experience in steel construction, Nauta Heeg has grown into a modern enterprise of substantial scale. The company specialises in heavy steel constructions for infrastructure and industry — such as bridges, fenders, offshore facilities and grid components. Its high production halls and cranes (with a lifting capacity of 80 tonnes) enable large-scale builds indoors. Located directly on navigable waters and close to a coating facility, the logistics flow efficiently.

In collaboration with its sister companies, Nauta Heeg is capable of delivering highly diverse and complex projects. A trusted steel construction partner with the scale and craftsmanship to meet today’s infrastructure and industrial challenges.

Clients

In 2024, Nauta Heeg worked on wave screens and guiding barriers for the Nieuwe Sluis in Terneuzen, fenders for cycle bridges on the Spoorbaanpad in Almere, and high-voltage substations for TenneT in Haaksbergen, Louwsmeer and Tytsjerk.

| Lifting capacity | 80 |

| FTE | 46 |

| Revenue growth 2019–2024 | 23% |

MF Emmen:

Mechanical engineering for industry, infrastructure and recycling

MF Emmen supports clients across a variety of sectors — from energy and food tech to infrastructure and recycling. The company develops and implements efficient solutions to optimise production processes. With a modern machinery fleet and highly skilled employees, MF Emmen delivers complex systems from design to completion. CNC turning, milling, drilling, metal cutting, welding and other operations are all carried out in-house. Our turnkey approach and extensive service relieve the client of all concerns.

MF Emmen stands for quality and client satisfaction, continuously responding to technological developments. Thanks to our in-house expertise and required certifications, we are a reliable partner for every project.

Clients

In 2024, MF Emmen worked on various installations and filtration tanks, including for Cosun Beet Company. Following the first drum filter in 2023, a second unit was commissioned in 2024 at the Vierverlaten site in Groningen. We also received assignments from Bronswerk Heat Transfer to machine plug and tube holes in heat exchanger headers.

| FTE | 67 |

TruSteel Energy:

Your partner for smart energy solutions

TruSteel Energy is an experienced partner in solar energy systems. Over the past years, we have installed solar panels on numerous rooftops. TruSteel Energy offers a single point of contact and delivers a complete solar panel system, including grid connection. In addition to solar power, we also specialise in other energy solutions such as energy storage (especially relevant in areas with grid congestion), energy management systems and EV charging stations.

Clients

In 2024, TruSteel Energy equipped several rooftops with solar panels, including at Equans in Emmeloord, VHM Machinery in Ens, and Broer in Creil.

TruSteel Infra:

Specialists in complex steel infrastructure projects

TruSteel Infra contributes to a safe, accessible and liveable infrastructure across the Netherlands. Our focus is not only on expansion, but also on the major renovation and replacement challenges the country will face in the coming decades. We work in close cooperation with clients and partners to build smart and sustainable steel solutions for complex civil works — including bridges, locks, weirs and pumping stations.

Our main clients include public authorities such as Rijkswaterstaat, provinces, municipalities and water boards. In 2024, TruSteel Infra worked on the construction of the Pijlebrug in Meppel, two bridges for the Gerrie Knetemannpad in Almere, and the Ringersbrug in Alkmaar.

TruSteel Recycling:

Trusted partner in waste and recycling solutions

TruSteel Recycling is a leading supplier of complete recycling systems and separate components. We focus primarily on sorting systems for processing construction, demolition, industrial and green waste. We deliver turnkey systems — including drum screens, air separators, danodrums and conveyor belts — as well as standalone components for separating various waste streams.

Existing systems can also be modified or expanded upon request. With our extensive experience and in-depth expertise, TruSteel Recycling has been a valued partner to many industries within the recycling sector. The organisation is set up to operate both nationally and internationally and is familiar with a wide range of contract formats.

Clients

In 2024, TruSteel Recycling delivered new recycling systems to waste processors such as AEB Amsterdam, replaced a drum at Attero in Wilp, and served multiple clients abroad.

The family business

We are a proud family business that has been passionately and purposefully building a wide variety of projects for over 45 years — across many different market segments. From innovative recycling installations to bridges and locks, from buildings to tippers and containers: at TruSteel Group, we deliver steel solutions across a broad range of sectors.

Our structure

What began in 1980 as a modest venture constructing barns and sheds has grown into a solid and ambitious player in the steel industry. Today, our group consists of eight leading steel-processing companies, employing more than 350 skilled professionals who apply their knowledge and craftsmanship every day.

Over the years, we have built a strong reputation in the Netherlands — and abroad. With annual revenue of €120 million, we are now one of the largest industrial employers in the northern Netherlands. But we are not only building exceptional projects — we are building lasting client relationships. We foster trust by delivering consistent quality and positioning ourselves as a reliable and experienced partner. Our approach is straightforward: we listen, make clear agreements and always honour them. This open and honest way of working allows us to not only meet but often exceed our clients’ expectations.

Collaboration is our foundation

Collaboration is central to everything we do at TruSteel Group. Not only with our employees, partners and clients, but also among the eight companies that make up our group. In 2024, we saw increasingly close cooperation between our divisions on several impressive projects. By combining expertise and leveraging economies of scale, we can deliver even more tailored and sustainable solutions. We manage the entire value chain — from concept to completion — which enables us to fully relieve our clients of all concerns.

Project highlights

We contributed to several large and complex projects. One example is the construction of a sorting plant for AEB Amsterdam, delivered by TruSteel Recycling in collaboration with MF Emmen, Kampstaal and Kamplacon. Another remarkable project was the construction of an 80-metre-long bridge in Wilhelmshaven, Germany, by our divisions Nauta Heeg and TruSteel Infra. The bridge was assembled in two parts and shipped by water to its final destination.

Other highlights include the collaboration between Kampstaal and Kamplacon on the construction of the parking facility for Ahoy Rotterdam and multiple data centres in Amsterdam, Frankfurt and Berlin. These examples demonstrate the strength of our internal cooperation and our capacity to successfully realise large, complex projects.

Building a more sustainable future

As a family-owned business, we feel deeply connected to the world around us. We want to make a difference today, while also contributing to a livable future for generations to come. That’s why sustainability is an integral part of our operations.

In 2024, we again critically examined our own impact and looked for smarter, cleaner and more socially responsible ways of working. We do this together — with our construction partners — building toward a more sustainable future. By continuing to innovate, improve processes and reduce our ecological footprint, we contribute every day to a future we can proudly pass on.

Social engagement in our regions

Alongside sustainability, social involvement is a key priority for us. We believe it is important to stay connected with the regions and communities in which we operate. That’s why we support many local cultural, sports and social initiatives and associations. We also support charitable causes nominated by our own employees — initiatives they are personally connected to.

New name and brand identity

In 2024, we proudly launched our new brand identity — a process we began in 2023. A key milestone in this rebranding was our name change from GB Steel Group to TruSteel Group. With the new name and accompanying visual identity, we aim to present a more unified and cohesive image. Each division continues to operate independently with its own area of expertise, but now under one recognisable and shared identity.

As part of our repositioning, we now operate under three new division names within the infrastructure, energy and recycling markets: TruSteel Infra, TruSteel Energy and TruSteel Recycling. This allows us to respond even more effectively to the specific needs of each sector — and to meet the growing demand for sustainable solutions.

- TruSteel Infra focuses on bridges, locks, weirs and pumping stations, maintaining the trusted quality and expertise of Nauta Heeg and MF Emmen. Clients can now rely on one central point of contact for tenders and inquiries.

- With the launch of TruSteel Energy, we respond to the increasing demand for sustainable energy solutions. In addition to solar panels, our services now include energy storage, energy management systems and charging stations — enabling us to contribute more broadly to the energy transition.

- The TruSteel Recycling division builds on more than 30 years of experience in designing and implementing high-performance recycling solutions. With our new name, we’re taking a major step in strengthening our international presence and global positioning in the recycling industry.

Staff celebration

We proudly presented our new group name and branding to our entire team during a festive launch party. The reveal was spectacular: an impressive laser show not only introduced the new name, but also powerfully conveyed our vision for the future. After the official reveal, the celebration began in full swing.

The Heeren van Aemstel Band delivered an energetic live performance, creating a fantastic atmosphere. At the various food stations, colleagues enjoyed a wide variety of dishes — from street food to international cuisines. The additional entertainment — including interactive games and surprise acts — completed the evening. We look back on a very successful night!

Brand roll-out

The new TruSteel Group brand identity has now been fully implemented across all our communications. From signage and wayfinding to letterhead, flags, company vehicles and buses — even sportswear and sponsor boards — the new brand is now clearly visible everywhere. The website has also been redesigned to reflect the new TruSteel Group look and feel, creating a strong and consistent brand presence.

Governance

Within TruSteel Group, each of our companies operates under its own name and is led by its own management team. However, we place a strong emphasis on collaboration and synergy within the group.

TruSteel Group is governed by a General Board, consisting of a CEO, multiple directors, a group controller and an HR manager. The administrative organisation is overseen by the group controller. Above the General Board is the Executive Board, made up of CEO Bob Soetekouw, Commercial Directors Rieks Jansen and Paul Kok, and Project Director Bas van Hoeve. The Executive Board reports to the Supervisory Board, which was established in accordance with legal requirements for corporate governance. Employee representation is ensured through a Group Works Council.

While women are active on the General Board, in the divisions, in staff positions and on the Supervisory Board, they remain underrepresented. Our HR policy recognises this imbalance and is committed to achieving a more equitable gender distribution.

Core values

As a family-owned company, we place great importance on building long-term and strong relationships — with our clients, employees and partners. Everything we do is guided by four core values: safety, sincerity and integrity, building trust, and our shared passion for steel.

SAFE WORKING — we work safely or not at all

At TruSteel Group, safety is our top priority — our safety mindset is always on. Every day, we strive to raise awareness of safety and to continuously improve. We do this by sharing knowledge, enforcing strict safety policies and educating our employees about potential risks in the workplace. Where necessary, we take preventive measures to eliminate unsafe conditions.

Our aim is to reduce unsafe incidents, such as absenteeism and accidents, and to create a workplace where everyone feels healthy, safe and motivated. That’s why we continue to invest in a safe working environment.

SINCERITY & INTEGRITY — true and truth

Sincerity and integrity are at the heart of everything we do. We believe that ethical behaviour must be embedded in our organisational culture. It defines what we stand for, how we behave and how we act — towards one another, our clients, our partners and the wider society. Honesty, ethics and transparency form the basis for this. It’s how we build sustainable relationships based on trust and mutual respect.

BUILDING TRUST — trust

At TruSteel Group, we design, produce and deliver high-quality steel projects. With years of experience in custom solutions, we have proven ourselves to be a reliable partner in the steel industry. Our focus is not only on delivering impressive results — but on building long-term relationships with our clients.

We earn trust by showing that we are experienced and capable. We do business in an open and honest way, we listen carefully, make clear agreements — and most importantly, we deliver on them. This is how we build trust and long-lasting partnerships.

PASSION FOR STEEL

What drives us is our passion for engineering. We thrive on complex challenges in construction, infrastructure, transport and industry. This passion fuels our commitment to support our clients with knowledge, creativity and problem-solving.

We know that, at the start of a project, not all answers are available. That’s exactly where we excel. Our structural engineers, technical designers and project managers think along, offer solutions and help shape the design. With the same energy and enthusiasm, we bring the concept to life — delivering results that make a real difference.

#wemakesteelwork

’Kampstaal awarded the 2025 Steel Prize for Amsterdam South Connection!’

Our impact

Topics like climate adaptation, CO₂ reduction, circular business practices and the energy transition are high on the societal agenda — and high on ours, too. As a family-owned company, we want to make a valuable contribution in these areas. We do this by making thoughtful decisions in our operations, always guided by our aim to act sustainably, responsibly, and with respect for people and the environment. Naturally, we also actively support the Dutch Bouwakkoord Staal (Steel Construction Agreement).

Our sustainability ambitions

To ensure a healthy, liveable world for current and future generations, significant progress is needed across many areas. The United Nations has translated this wide range of societal challenges into 17 concrete goals for 2030 — the Sustainable Development Goals, or SDGs. TruSteel Group actively supports these goals and has incorporated them into our sustainability strategy.

We focus primarily on six of the 17 SDGs — where we believe we can make the biggest impact through our activities. These include:

- developing affordable and clean energy

- creating employment and economic growth

- building sustainable infrastructure and industrialisation

- enabling sustainable buildings, cities and communities

- encouraging responsible production

- taking climate action, with CO₂ footprint reduction as a key metric

Naturally, we aim to perform well on the other goals too.

'Is steel losing to wood as the building material of the future?'

Bob Soetekouw in conversation with ChatGPT

Our internal efforts

With our sustainability strategy, we contribute to our mission of creating a healthy living environment. Two pillars shape this strategy — smart thinking and sustainability — which we apply throughout all our projects and business processes. This means continued investment in innovative technologies and materials that reduce our ecological footprint and support a circular economy.

We’re achieving this through:

- generating green energy with TruSteel Energy solar panels on our rooftops

- promoting reuse and circular construction

- switching to electric vehicles

- active involvement in the Bouwakkoord Staal — both on the steering committee and in the core team

These efforts help promote the reuse of buildings, materials, products and raw materials, and actively reduce our CO₂ emissions. Between 2015 and 2024, we cut our emissions by over 44%. In the coming years, we aim to reduce them even further.

We’re also expanding our sustainability offering — giving clients smarter choices for sustainable steel construction. It’s part of how we take responsibility as a group and work together toward a cleaner, greener and safer living environment.

Talent development

Our people come first. We consider it our responsibility to provide a safe and healthy working environment where our employees can perform at their best and continue to grow. We offer plenty of opportunities for development and personal growth.

To achieve our growth ambitions, we not only invest in our current workforce, but we also actively seek out new talent. Finding skilled professionals with the right expertise remains a challenge. That’s why, in 2024, we further professionalised our recruitment efforts and placed even more focus on employer branding and labour market communications. These efforts helped strengthen our position as an employer and attract the right people.

We also believe it’s important to promote technical education in our region. We do this not just by reinforcing our own position as an attractive employer, but also by working with schools and industry peers to improve the image of the construction and manufacturing sectors.

How we do this

By working together

Since 2020, we’ve been part of the Innovation Cluster Noordoostpolder – a collaboration between nine manufacturing companies. Our goal is to inspire students to pursue careers in technology, share knowledge, help our teams grow and drive innovation together.

In 2024, we also worked closely with schools to better align education with labour market needs. This collaboration helps improve the image of our sector and encourages young people to consider a career in technology.

By investing in young talent

We offer students hands-on vocational work-and-learn placements (BBL). During their BBL programme, students attend school one day a week and spend the rest working at one of our divisions. They gain valuable experience under the guidance of our skilled professionals. We offer various BBL tracks, ranging from level 2 vocational training to HBO (higher professional education) programmes.

By offering a glimpse into the world of technology

We believe in inspiring kids from a young age. That’s why we give guest lectures at schools and regularly open our doors to primary and secondary school students. We organise tours and workshops to show how exciting and rewarding a technical career can be.

Each year, you’ll find us at events like On Stage and Techniek Tastbaar in Emmeloord, Meppel and Sneek.

’We build robust steel structures while fostering our people’s growth’

Lookback

Financial results 2024

The results for 2024 are encouraging, especially when compared to 2023. Revenue increased by 40%, reaching more than €120 million. At the same time, return on equity rose by 10% to over 16%. The revenue growth in 2024 was largely driven by a strong order book in 2023. Many projects experienced a delayed start, resulting in underperformance that year. These projects have now come to fruition.

The strongest performance came from the non-residential construction sector. Kampstaal and Kamplacon continued working on data centre projects, among others, and achieved approximately 60% revenue growth. This is particularly noteworthy given that overall construction activity in the Dutch non-residential sector shrank by 11% (according to the EIB). Part of this growth came from projects in Germany. Maintaining both quality and profitability at this pace is impressive and reflects internal investments in both technical and social innovation — our large-scale lean programme being a prime example.

Still, there are areas of concern. Revenue and results declined in infrastructure and mechanical engineering. The Dutch programme to replace and renovate bridges and locks has yet to gain real momentum. As a result, investments in MF Emmen and Nauta Heeg have not yet yielded returns. Vossebelt, too, had a difficult year. Longer lead times and inflation led to order write-downs, while staff turnover impacted stability and results. Investments in process improvement and organisational development are expected to help recovery.

Bob Soetekouw on organisational development and strategy

“We keep asking ourselves: how do we stay in control while growing?

With figures like these, quality and profitability don’t just follow automatically. Our organisation must scale across all dimensions. Since 2015, strategic development has been a key focus within TruSteel. Our multi-year plans are designed to enable sustainable growth — and with success.

Since 2015, TruSteel has grown by an average of 15% per year, while return on equity has remained steady at 17%. This demonstrates the value of long-term thinking. Of course, there are years with above-average growth and years that fall behind. Success is never guaranteed, and it would be naive to believe everything is within our control.

We’re not chasing quick wins — we believe in sustainable growth. This game doesn’t end after 90 minutes.”

In 2025, TruSteel is working on a new strategic plan. Read more about it in the ‘Strategy’ chapter.

Turnover and profit on equity capital

![]() Construction and recycling transport

Construction and recycling transport ![]() Steel construction infra-industry

Steel construction infra-industry![]() Commercial-industrial structures & cladding

Commercial-industrial structures & cladding

![]() Return on equity

Return on equity

Investments

In 2024, we invested a total of €4.7 million — a modest amount overall. About one-third was spent on new machinery. Kampstaal initially focused on improving its beam line processes and later began preparing to replace its shot blasting machine. MF Emmen invested in new milling machines, enabling it to handle larger components.

Read more about MF Emmen’s upgraded machinery here.

Other investments included new transport equipment — such as a truck with a truck-mounted crane — giving Kampstaal more flexibility when loading and unloading at construction sites. Passenger cars were also added to the fleet to accommodate the growing workforce.

We also invested in a new joint office for the project management teams of Kampstaal and Kamplacon — a team that now quite literally operates under one roof. Located behind the striking corten steel façade along the A6 near Emmeloord, this new space supports seamless collaboration.

Investments 2023, 2024 en 2025

X € 1.000

![]() 2023

2023 ![]() 2024

2024 ![]() 2025 (prognosis)

2025 (prognosis)

Liquidity and solvency

The group’s liquidity position improved further in 2024. Working capital and investments were financed from existing resources — no new capital was raised. Although current liabilities increased, resulting in a lower current and quick ratio (1.61 and 1.43, respectively), both figures remain healthy thanks to strong performance and improved debtor payment terms. Solvency is also robust at over 50%.

Debt / EBITDA

Solvency

Return on equity

Current ratio

Highlights 2024

Exhibitions and Events

In 2024, we were once again active at several (inter)national trade fairs and events. These provided the perfect opportunity to present our latest innovations and connect with new and existing contacts. Below is an overview of the events we attended:

Infra Relatiedagen in Hardenberg

In February, we exhibited together with Nauta Heeg and MF Emmen at the Infra Relatiedagen in the Hardenberg Event Hall. It was a successful three-day event where we met with partners and prospects, shared knowledge, and explored new opportunities. We look back on a highly productive edition.

Kipper Event in Harderwijk

On Friday 7 and Saturday 8 June, the Kipper Event took place at the Bouw & Infra Park in Harderwijk. Following the success of its first edition, the event was held at a more central location this year. Vossebelt was once again present and welcomed a large number of visitors to our stand. A successful event with great visibility for our brand and solutions.

Plastics Recycling Show Europe (PRS Europe)

At the end of June, TruSteel Recycling participated in the Plastics Recycling Show Europe at the RAI Amsterdam. This international trade fair is fully dedicated to plastic recycling and attracts professionals from across the industry. The event was a great opportunity to share knowledge, discover new trends and present our expertise in sustainable recycling solutions.

Recycling Trade Fair in Gorinchem

In November, TruSteel Recycling was also present at the Recycling Trade Fair in the Gorinchem Event Hall. Just like at PRS Europe, this event was an excellent occasion to network with industry peers and share insights. The fair proved to be highly valuable and successful once again. We look back on a fruitful year of exhibitions and events!

TruSteel Group Safety Day

Kampstaal Meppel at Techniek Tastbaar

Introducing Our New Exhibition Stand – TruSteel Recycling

Strategic direction

Closing chapter of the 2021–2024 strategy

In 2024, we concluded our 2021–2024 strategic period. This plan focused on strengthening our position in key growth markets, investing in sustainability, digitalisation and innovation, and developing our organisation and talent.

We made significant progress during this period. We strengthened our market position and successfully entered new markets beyond the Netherlands. We developed sustainable solutions for the recycling industry, applied smart technologies and adopted more circular construction methods. We optimised our business processes to reduce CO₂ emissions, generated more renewable energy, and promoted the reuse of materials. In terms of digitalisation and automation, we implemented new IT hardware and software and invested in machinery and robotics to accelerate and optimise production.

We also focused strongly on creating a safe and healthy working environment for our employees. In addition, we improved our talent acquisition efforts. By optimising our recruitment activities and strengthening our employer brand, we attracted more qualified candidates and positioned ourselves more strongly as an attractive employer.

New strategic direction 2025–2030

In 2024, we launched a new strategic development programme for 2025–2030, which we completed in March 2025. The main drivers behind this strategy are:

- to continue flourishing as a family business under the current shareholders;

- to achieve sustainable growth that prioritises customers, employees and society, and that results in healthy profits;

- to make TruSteel one of the most sought-after employers and suppliers in Northwest Europe for innovative steel solutions in our key market segments.

To realise these ambitions, we are convinced that we must take the following steps:

Together we make steel work #wemakesteelwork

We pursue a proactive, market-oriented approach to lead rather than follow the (international) market. This means putting customer needs at the heart of our promises, products and services across the entire organisation. It requires a transition from location-based operations to market-focused business units, enabling us to better leverage networks, knowledge and capabilities.

Sustainable growth in revenue and profit

We believe in using our combined expertise to create more value in two-stage and design & construct contracts. These contract types are becoming standard in the infrastructure and industrial sectors. They focus on close collaboration with clients on project scope, requirements and risk management. We see this shift reflected in our strategic partnerships in the utility building segment, particularly for data centres and parking facilities.

This way of working calls for further development of our people’s capabilities: from smarter steel design and multidisciplinary teamwork to improved contract and project management and production efficiency. We will also continue to expand our capacity for production automation and preservation to increase flexibility and reduce lead times. This gives us a competitive edge and helps us stay ahead of the market.

Happy employees, happy customers

We believe that satisfied, healthy employees are essential for our success — and for creating satisfied customers. Key success factors that align with our core values include: enjoying our work, being curious, staying open to other perspectives and suspending judgement to make better decisions. In addition, we aim to better leverage technologies like AI to make work more enjoyable and efficient: work smarter, not harder, and become more agile as a result.

Achieving this will require training and leadership development focused on strengthening and nurturing each person’s unique talents.

Outlook

Market developments and outlook for 2025

Looking ahead, the picture is mixed. Based on the figures, the future looks bright. By the end of 2024, our order book had grown by 20% compared to year-end 2023, reaching €141 million. Most of this was related to utility construction. Thanks to an integrated solution combining steel structures, roofs, façades and related services, Kampstaal and Kamplacon have secured a unique position in the data centre sector. These projects are currently located mainly in the Netherlands and Germany, and we are preparing to expand into new geographic markets.

In other markets, the outlook varies. The first successes are visible from our investments in the infrastructure team (TruSteel Infra, active in the bridge and sluice segment), but they are still in an early stage. The same applies to the recycling market. This spring, we carried out a major project for AEB Amsterdam. TruSteel Recycling replaced a large part of the municipal waste separation line, working closely with almost all TruSteel divisions for structural supports, platforms and building modifications.

‘TruSteel Group kicks off the year with a record-breaking project portfolio’

At the same time — as of May 2025 — we are seeing uncertainty in the market. Investment decisions are taking longer, which is affecting order intake. We attribute this to the unstable geopolitical climate, with the ongoing trade conflict between China and the United States and the war in Ukraine. A strong order book limits our exposure, but it is not a guarantee for optimal utilisation. In our experience, many projects begin later than planned. As a result, we are cautious in our expectations for 2025, though we remain optimistic. TruSteel Group is in excellent financial health and has solid reserves.

Our broad portfolio and ability to share work and expertise across divisions help spread risk. We also see new market opportunities to strengthen our strong order book. Several of our sites are now equipped to support upgrades to the energy network. We are an experienced partner in the urgent task of replacing and renovating infrastructure. And with our quality and safety certifications, we are well-positioned to serve a wide range of industries. Backed by experienced project management, international know-how and a solid operational foundation, we are ready to expand our international presence.

We continue to evolve as an organisation — because by 2030, we aim to be the most sought-after steel fabricator and employer in the Netherlands and a top-15 player in Western Europe.

Our Vossebelt tipper in action

Specialist in steel processing

Green façades by Kamplacon